The vibratory feeder brings the springs in a vertical tube. A feed device even lets one spring pass the tube and feeds a round transport table which has six holes to hold the testing parts and gets moved step-by-step in clockwise direction. Having passed the feeder the springs are moved to the certain prestressing units followed by a measuring unit. Having passed all the units the springs are sorted in three definable groups.

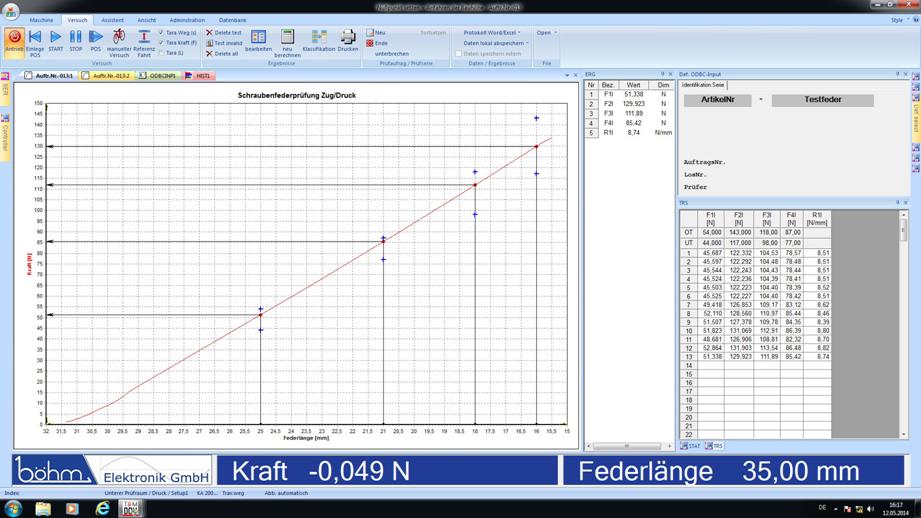

The tester has a rigid load frame with a servo drive. It can perform various test sequences either length regulated, load regulated or combined. Tests of free length, blocklength, load at length, length at load, rate, load/length and rate/length diagramm are possible. The results can be archived or exported in Excel format to other CAQ systems.

Automatic prestressing and testing machine SP-1D

| 0 - 100 Newton | |

| Resolution: | 0,001 N |

| Max. prestressing load: | 100 N |

| Max. load range: | 100 N |

Automatic prestressing and testing machine SP-2D

| 0 - 1.000 Newton | |

| Resolution: | 0,01 N |

| Max. prestressing load: | 1.000 N |

| Max. load range: | 1.000 N |

Also available with other load cells.

| Max. spring length: | 80 mm |

| Max. spring dia: | 28 mm |

| Max. speed: | 3.000 parts per hour |